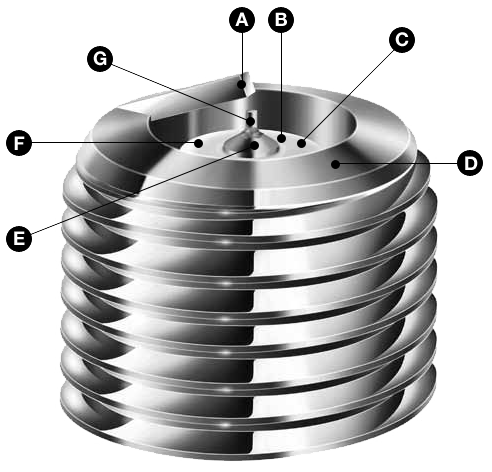

A. 100% PLATINUM 0.8 MM GROUND ELECTRODE

Platinum has a higher melting point than the nickel alloys used in conventional spark plug ground electrodes. This feature reduces wear and problems such as melting the ground electrode under severe driving or race conditions. In addition, the platinum alloy used in the 0.8mm ground electrode is produced without the need for fusing or bending, which increases durability and virtually eliminates residual stress.

B. PATENTED SELF-CLEANING SPARK

A small gap has been developed around the tip of the center electrode and insulator. If the plug develops carbon build-up and bridging occurs, electrical discharges in this section burn away any carbon deposits and cleans the insulator. This technology has been patented by DENSO (Japanese patent No. 2727558).

C. SILICONE OIL COATING

For racing vehicles, starting problems caused by carbon deposits and bridged plugs before the start of a race can be fatal. To prevent this, a film of silicone oil is applied to the insulator. The water repellent properties of silicone oil keep the insulator surface free from moisture and carbon to prevent any losses in plug insulating performance.

D. BEVELED HOUSING SIDE

The bevel on the side of the housing has been increased in size to improve resistance to abnormal combustion. Furthermore, they also make possible the discharge of residual gases and entry of fresh gases; improve self-cleaning performance, which helps reduce fouling of the plug.

E. 360º LASER WELDING PROCESS

360° laser welding* is used to create a seal so reliable the electrode resists wear even in the harshest driving conditions.

* DENSO patented the 360° laser welding method in Japan and the United States. (Japanese patent No. 2921524, U.S. patent pending).

F. RACING INSULATOR

Through DENSO’s involvement in motorsports, we have engineered a new insulator that is 20% stronger than insulators previously used.

G. ULTRA-FINE 0.4-MM DIAMETER IRIDIUM CENTER ELECTRODE

The new DENSO Iridium alloy, with an extremely high melting point, is used to create the world’s smallest center electrode allowing the voltage requirements to be significantly reduced and greatly improving ignition performance.

This new Iridium alloy achieves its particular characteristics through a unique material structure (*1) and production method (*2).

*1 Small amounts of rhodium are added to the alloy to increase high-temperature oxidation resistance. (Japanese patent 2877035, U.K. patent 23023767)

*2 A fusion method is used to form the center electrode, instead of the conventional sintering method. (Japanese patent 3000955, U.S. patent 5977695)