System Diagnosis

Proper vehicle diagnosis requires a plan before you start

Following a set procedure to base your troubleshooting on will help you find the root cause of a problem and prevent unnecessary repeat repairs.

STEP ONE: Understand the Customer’s Concern

- Information collection beyond the basics.

- Questions asked MUST be related To the system you will be working on and the customer complaint

STEP TWO: Check for Technical Service Bulletins

- Every vehicle that comes into the shop for a repair (not necessary for routine maintenance) should be checked for TSB’s, This can save you hours of troubleshooting.

STEP THREE: Conduct a Systematic Diagnosis

- This step will be different for every system

- Follow the troubleshooting steps for the system you are working on.

- Make sure to check EVERY component of the system and that they are in proper working order.

- Document your diagnosis including tests and results

STEP FOUR: Complete and Confirm the Repair

- Make sure you have taken care of the customer’s concerns.

- Try to duplicate the conditions that were present when the vehicle failed

The Diagnostic Process

STEP ONE: Confirm the Customer’s Concern

What is the concern?

- No cooling

- Poor cooling

- Airflow issue

How often?

- One time

- Intermittent

- Constant

When did it happen?

- Day

- Time

- Ambient temp

Conditions?

- Highway

- Local

- Traffic

- Vehicle speed

Who was operating the vehicle?

- Primary Driver

- Other

Know the facts vehicle air conditioning expectations differ from driver to driver

STEP TWO: Confirm the Customer’s Concern

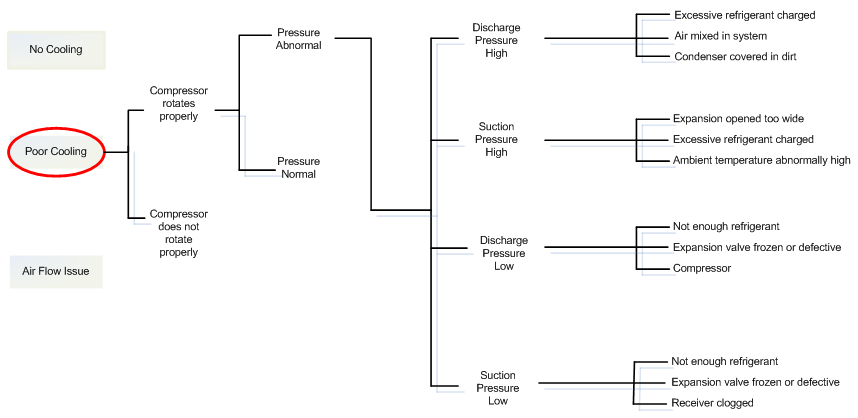

Systematic Diagnosis

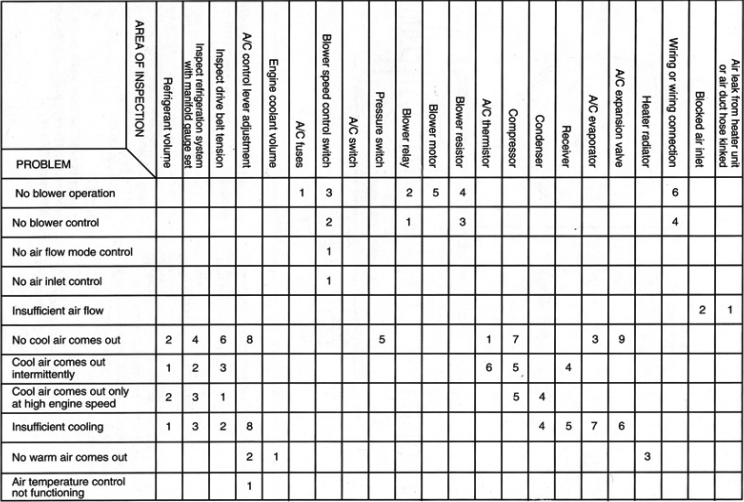

This table shows the priority in which each problem should be inspected, after identifying the problem use the area of inspection in number priority, then repair or replace as necessary.

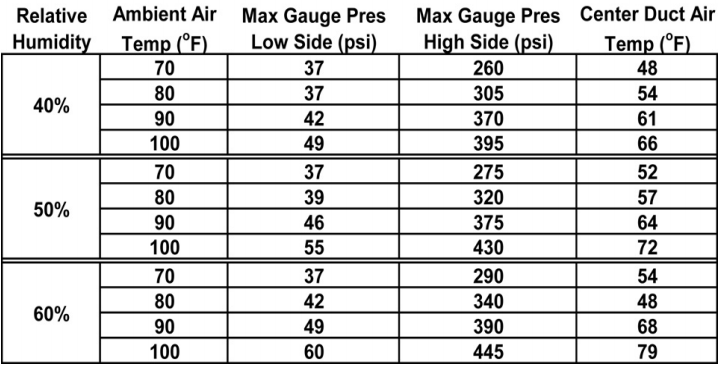

Typical pressure readings

Temperature/Humidity/Pressure Relationships for R134a

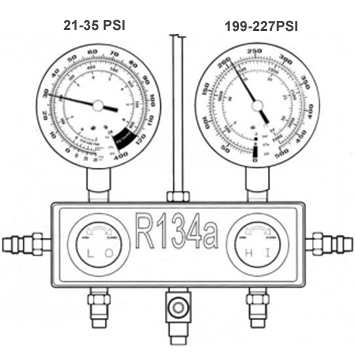

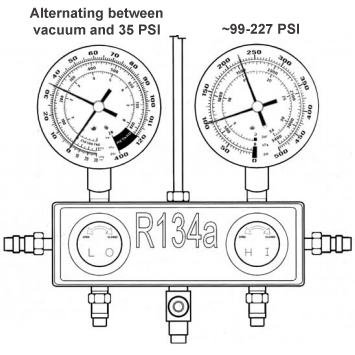

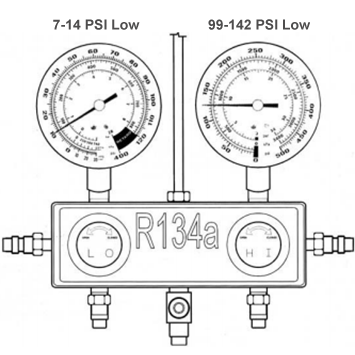

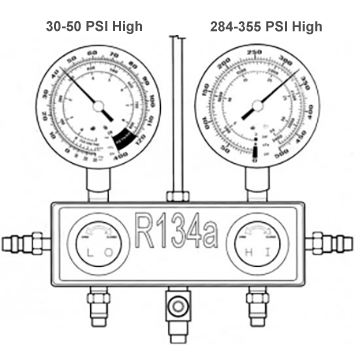

Manifold Gauges (sample readings)

86º – 95º F | 1500 RPM | Max Cool | High Blower

- Normal Reading

- Moisture Entered in Cycle

- Insufficient Refrigerant Refrigerant

- Fails to Circulate

- Excessive Refrigerant or Insufficient Condenser Cooling

- Expansion Valve Trouble (Opens Too Much) or Improper Installation of Heat Sensitizing Tube

- Air Entered In The Cycle

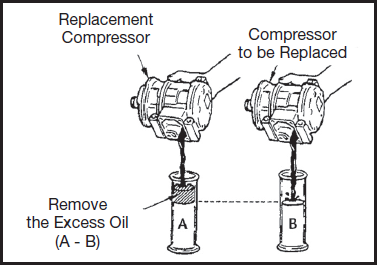

Compressor Replacement

Compressor Preparation

- Slowly release the pressure from the Schrader valve located on the compressor shipping plate(s) or hose caps

- To prevent the loss of refrigerant oil:

- Place the compressor on a flat surface with the shipping plate(s) or hose caps in an upright position

- Then remove and save the shipping plate(s), O-ring(s), and mounting bolts or hose caps.

- Remove the service valve(s) or hose caps from the old compressor. Make sure service valves and O-ring surfaces are clean.

- Verify the level of compressor lubricant

Flushing the A/C System

What is the purpose of flushing the A/C system

- Remove contaminates that are in the A/C system

- Most of the contamination is caught up in the oil, not the refrigerant

When to Flush

- Oil Contamination

- Non pure refrigerant (R12 or R134a) used

- Compressor Failure

- Receiver/drier or Accumulator failure (descant)

What to Flush

- Hoses and Piping (without inline mufflers)

- Condenser (Round Tube and Fin/Serpentine)

- Evaporator (Round Tube and Fin/Serpentine)

- Compressor (Swash plate/Scroll/Through Vane)

What NOT to Flush

- Hoses and Piping with inline mufflers

- Condenser (Flat Tube Multi flow)

- Evaporator (Flat Tube Multi flow)

- Compressor (Variable Displacement)

- Complete system (Closed loop)

The system should be broken down to as many individual components as possible. Do not try to flush the entire high side of the A/C system as one long piece with hoses and the condenser attached.