System Diagnosis

Proper vehicle diagnosis requires a plan before you start

Following a set procedure to base your troubleshooting on will help you find the root cause of a problem and prevent unnecessary repeat repairs.

STEP ONE: Understand the Customer’s Concern

- Information collection beyond the basics.

- Questions asked MUST be related To the system you will be working on and the customer complaint.

STEP TWO: Check for Technical Service Bulletins

- Every vehicle that comes into the shop for a repair (not necessary for routine maintenance) should be checked for TSB’s, This can save you hours of troubleshooting.

STEP THREE: Conduct a Systematic Diagnosis

This step will be different for every system

- Follow the troubleshooting steps for the system you are working on.

- Make sure to check EVERY component of the system and that they are in proper working order.

- Document your diagnosis including tests and results.

STEP FOUR: Complete and Confirm the Repair

- Make sure you have taken care of the customer’s concerns.

- Try to duplicate the conditions that were present when the vehicle failed.

O2 Sensor VS Air Fuel Ratio Sensor

Oxygen Sensor bases have many holes

Air/Fuel Sensor bases have fewer holes

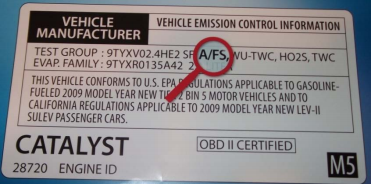

Here’s where you find the sensor type on the Vehicle:

This label shows HO2S (or O2S)

This label shows A/FS*

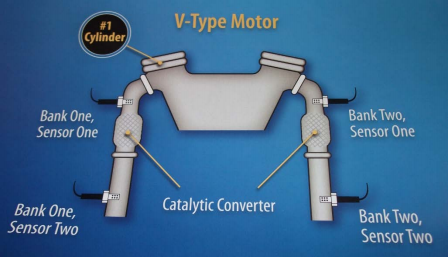

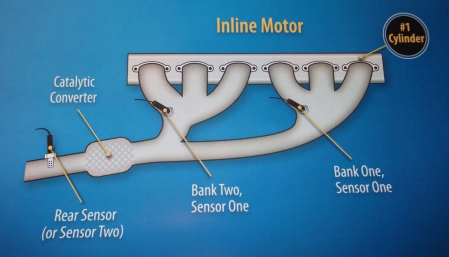

Sensor Location

#1 Cylinder is the key to locating the Oxygen Sensor

To locate bank one / sensor one, the key is to identify the # 1 engine cylinder.

In a V-type motor, sensor one (s) are in the exhaust system before the catalytic converter.

In an inline motor, the rear sensor (or sensor two) is in the exhaust system after the catalytic converter

O2 Sensor

Check the voltage signal

Using a 10-megaohm digital voltmeter Hook up the voltmeter’s red probe to the sensor’s signal wire and the black probe to engine ground. (use back probe method, DO NOT pierce the wire)

- Start the engine and let it idle for about two minutes while watching the digital reading on the voltmeter.

- It should be fixed for a short period at around 0.1 or 0.2 volts.

- After two or three minutes, the voltage reading will begin to fluctuate between 0.1 and 0.9 volts.

- If the sensor takes four minutes or more to begin fluctuating, replace it.

- Record the lowest and highest voltage reading from the voltmeter in any one-minute period.

- The voltage should fluctuate constantly between 0.1 and 0.9 volts.

- Replace the oxygen sensor if the voltage:

- Goes above this range,

- Remains below 0.5 volts

- Stays fixed at a particular voltage

- Open and close the engine throttle with a quick motion.

- The sensor’s output voltage should go up and down accordingly

Data Interpretation

O2 Sensor voltage

The O2 sensor normally alternates between 0 V and 1 V. When the value is fixed (stuck) at either 1 V or 0 V, investigate the cause of richness or leanness.

Fixed at 1V | Fixed at 0V |

|---|---|

Inspect weather something is causing a rich air-fuel ratio (see list below) If there are no abnormalities found replace the O2 sensor | Inspect weather something is causing a lean air-fuel ratio (see list below) If there are no abnormalities found replace the O2 sensor |

Possible causes of a Rich Condition

Possible causes of a Lean Condition

Plugged air filter

Faulty air mass meter

Faulty idle control valve

Faulty fuel injectors

Fouled spark plugs

Ignition timing

Faulty air fuel sensor

Associated wiring

Faulty ECU

Faulty MAP sensor

Faulty fuel pressure regulator

Restricted fuel return line

Faulty ignition wires

Faulty oxygen sensor

Faulty EVAP

Engine coolant temperature

Possible causes of a Lean Condition

Vacuum leak

Faulty air mass meter

Faulty MAP sensor

Faulty fuel pressure regulator

Restricted fuel filter

Faulty PCV

Exhaust gas leak

Faulty air fuel sensor

EGR valve

Faulty ECU

Faulty air flow meter

Faulty idle control valve

Faulty fuel pump

Faulty fuel injectors

Associated wiring

Faulty oxygen sensor

Ignition timing