System Diagnosis

Proper vehicle diagnosis requires a plan before you start

Following a set procedure to base your troubleshooting on will help you find the root cause of a problem and prevent unnecessary repeat repairs .

STEP ONE: Understand the Customer’s Concern

- Information collection beyond the basics.

- Questions asked MUST be related To the system you will be working on and the customer complaint

STEP TWO: Check for Technical Service Bulletins

- Every vehicle that comes into the shop for a repair (not necessary for routine maintenance) should be checked for TSBs, This can save you hours of troubleshooting.

STEP THREE: Conduct a Systematic Diagnosis

- This step will be different for every system

- Follow the troubleshooting steps for the system you are working on.

- Make sure to check EVERY component of the system and that they are in proper working order.

- Document your diagnosis including tests and results

STEP FOUR: Complete and Confirm the Repair

- Make sure you have taken care of the customer’s concerns.

- Try to duplicate the conditions that were present when the vehicle failed

Starting System Troubleshooting Chart

| Symptom | Possible Cause | Corrective Action |

|---|---|---|

| Engine will not crank | Dead battery | Check battery state of charge. Recharge if possible. Replace if necessary/td> |

| Melted fusible link | Replace fusible link | |

| Loose connections | Clean and tighten connections | |

| Key switch or start switch contacts in poor condition | Replace switch as necessary | |

| Solenoid hold-in coil open. Pull-in coil open or shorted. | Replace starter | |

| Solenoid contacts worn away | Replace starter | |

| Mechanical problem in engine | Check engine | |

| Engine cranks too slowly to start | Weak battery | Check battery. Recharge if possible. Replace if necessary |

| Loose or corroded connections | Clean and tighten connections | |

| Faulty starter | Test starter, Replace if necessary | |

| Starter spins, but engine will not crank | Faulty over-running clutch | Check over-running clutch, replace starter if necessary |

| Damaged or worn starter pinion gear or engine ring gear. | Check gears for damage or wear. Replace starter or ring gear |

Starting System inspection checklist

Begin with a thorough visual inspection of system and components

System tests:

Battery

- Load test

- Confirm charging system operation

System cables & wires

- Make sure all connections are clean and tight

- Check wires for fraying, insulation damage, and other physical damage

Voltage drop test

- Check voltage drop on the complete circuit

- If a problem is detected check the positive side and negative side separately to isolate problem

Check voltage at “KS” terminal on the starter with the ignition switch in the start position

- Typically 11.4-volt minimum (check vehicle service manual for correct specification)

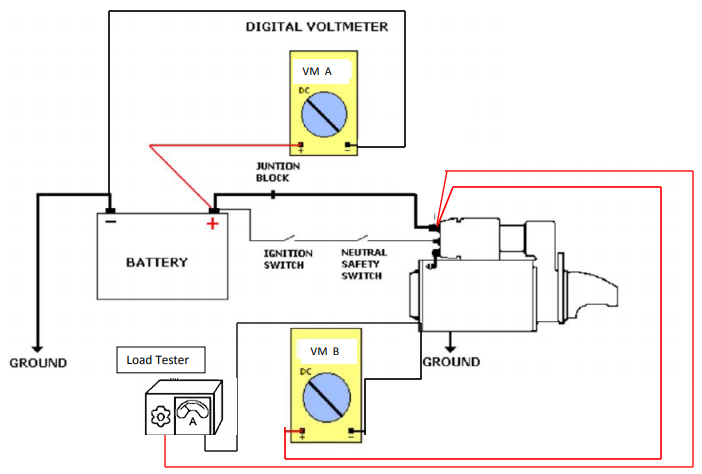

System voltage drop test

The diagram shows a carbon pile tester. Test can be done with electronic system tester, follow instructions included with the tool.

Subtract (-) VM B from VM A. Loss not to exceed 0.5V.

Proceed to positive & negative cable. Voltage loss tests if total loss exceeds specs.

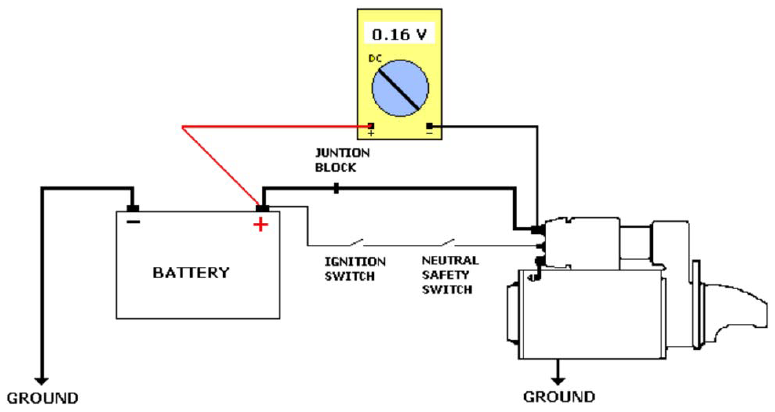

Positive side voltage drop test

Test can be performed with:

- Electronic tester

- Carbon pile load tester

- Cranking engine (If cranking engine)

- Disable the fuel or ignition system to keep the engine from starting during the test

- DO NOT crank the engine for longer than 10 seconds at a time

- Wait a minimum of 60 seconds before cranking engine again to cool the starter

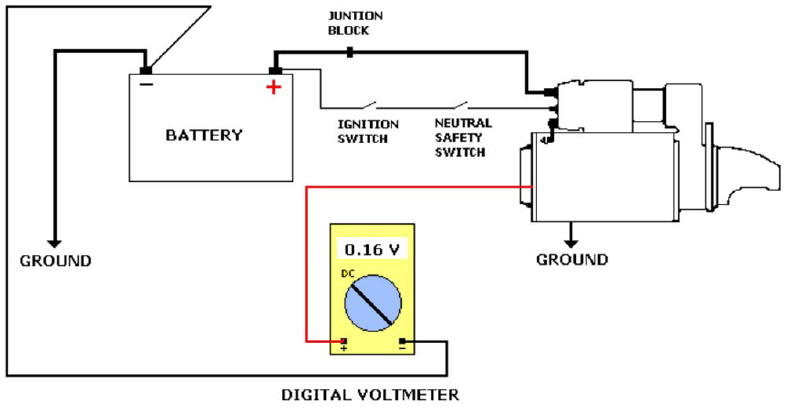

Ground side voltage drop test

Test can be performed with:

- Electronic tester

- Carbon pile load tester

- Cranking engine (If cranking engine)

- Disable the fuel or ignition system to keep the engine from starting during the test

- DO NOT crank the engine for longer than 10 seconds at a time

- Wait a minimum of 60 seconds before cranking engine again to cool the starter