Iridium Power Gapping Tips

Before attempting to gap any DENSO Iridium Power spark plug, please review the specification chart in the front of this catalog to verify the factory-preset gap. In most cases your Iridium Power plugs do not need to be gapped. Even with small variations in the factory set gap the ultra-efficient firing power design will compensate for those small variations. Should you decide to re-gap your Iridium Power plug, use extreme caution as improper gapping may damage or destroy the Iridium center electrode or porcelain center.

To increase the gap size:

Step 1: Use needle nose pliers or spark plug gapping tool to bend the ground strap up to the desired height. DO NOT LET THE PLIERS OR GAPPING TOOL TOUCH THE IRIDIUM CENTER ELECTRODE OR PORCELAIN.

Step 2: Re-check the gap with a calibrated gapping tool.

To decrease the gap size:

Step 1: Use the same method as above, however, bend the ground strap down to the desired height. DO NOT LET THE PLIERS OR GAPPING TOOL TOUCH THE IRIDIUM CENTER ELECTRODE OR PORCELAIN.

Step 2: Re-check the gap with a calibrated gapping tool. WARNING: Failure to follow these directions may permanently damage the spark plug. Note: Never use a round gapping tool to check the gap or to increase or decrease the gap setting.

| PLUG SIZE | CAST IRON HEADS | ALUMINUM HEADS | ||

|---|---|---|---|---|

| N-m* | lb-ft | N-m* | lb-ft | |

| 10mm FLAT SEAT | 10-15 | 7-11 | 10-15 | 7-11 |

| 12mm FLAT SEAT | 15-25 | 11-18 | 15-25 | 11-18 |

| 14mm FLAT SEAT | 35-40 | 26-30 | 20-30 | 15-22 |

| 14mm TAPER SEAT | 9-20 | 7-15 | 9-20 | 7-15 |

| 18mm FLAT SEAT | 43-52 | 32-38 | 38-46 | 28-34 |

| 18mm TAPER SEAT | 20-27 | 15-20 | 20-27 | 15-20 |

Installation Procedure

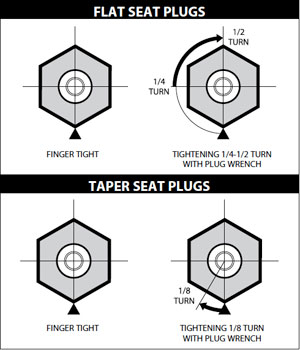

Whenever possible, it is recommended that the spark plug be installed using a torque wrench. If a torque wrench is not available, tighten in the following manner:

- The threaded area of the cylinder head must be clean.

- Finger-tighten the spark plug into the cylinder head. With a plug wrench, tighten about 1/4 to 1/2 turn (about 1/16 turn for a taper seat plug).

- Over-tightening may cause distortion of the plug housing and in extreme cases, engine damage. Therefore, proper installation is important for the spark plug’s performance and life.

TORQUE RECOMMENDATION

The table on this page gives the recommended torque for proper spark plug installation. Improper installation may cause poor performance, and even result in engine damage.

Note: The installation torque values shown above apply to new spark plugs without lubricating the threads. If threads are lubricated, the torque value should be reduced by approximately 1/3 to avoid overtightening.

*1N•m=0.1020kgf•m

This guide is provided for informational purposes only. Always seek the advice of a trained professional before servicing any engine. DENSO is not responsible for the use or misuse of this information and any results thereof. Specifications are subject to change without notice.